Divider

| Catalogue |  | Tech Sheet |  |

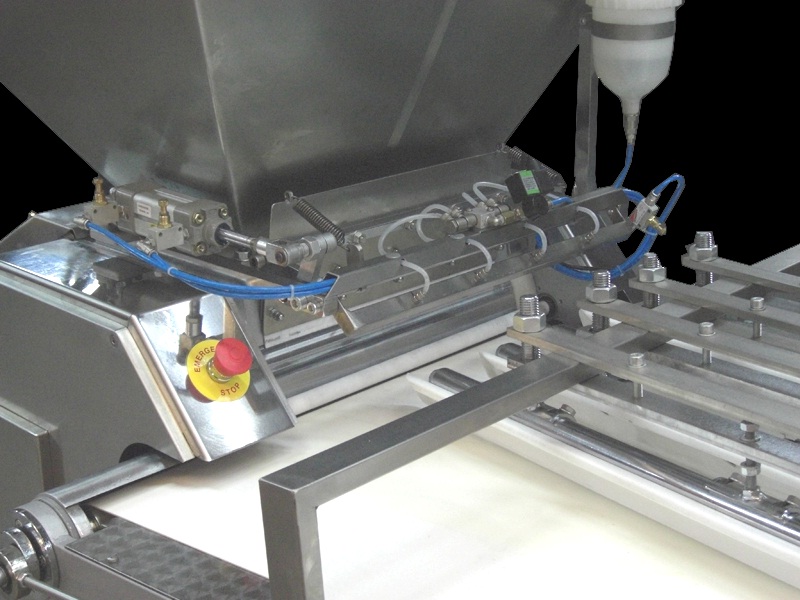

DIVIDER MODEL 93

The divider model 93 from Ciberpan is an accurate and robust machine. Its function is to divide the bread dough in portions with the desired weight. It is a volumetric divider. The dough is absorbed by a piston, after it is compressed and expeled. With this system it is obtained a good weighing accuracy and the dough is not punished.

Features:

-Maximum weight error 2% (for fresh dough without fermentation).

-The machine can divide dough with a content of water between 50 and 65% (with rounder) and higher than 65% (without rounder).

-Production 1000-2400 pieces/hour..

-Piececounter that allows the user to select the number of pieces to be made.

-Oiling system with minimum consumption.

-PVC conveyor belt.

-Rounder made of non-sticking teflon, adjustable to obtain a better rounding.

-Stainless steel hopper covered with non-sticking teflon, 40 L capacity.

-Stainless steel covering.

-Flour sprinkler.

Optional:

-Hopper of 80, 150 or 200 L capacity.

-Multiple piston: 2, 3, 4 y 5 pistons (maximum diameter of the piston decreases as increasing the number of pistons).

-Conveyor belt with independent motor: possibility of doubling the maximum weight.

-Automatic speed control by means of frecuency inverter.

-Weight regulation motor actioned.

Dough weight range:

| Diameter (mm.) | Min.(gr.) | Max(gr.) |

| 60 | 20 | 200 |

| 80 | 25 | 300 |

| 90 | 30 | 400 |

| 110 | 50 | 600 |

| 120 | 80 | 950 |

| 135 | 140 | 1300 |

DIVIDER MODEL 93-2P

The divider 93-2P is the appropriate model for big productions. Its difference with the standard model is that this one has 2 pistons, therefore 2 portions of dough are obtained in each cycle instead of only one.

The capacity of production is doubled, reaching the amount of 4800 pieces/hour.

In this model the maximum diameter of the piston is 90mm, therefore the maximum weight that can be obtained is 450g.

DIVIDER MODEL 93-4P

The divider 93-4P is appropriate for very big productions. Its difference with the standard model is that this one has 4 pistons, therefore 4 portions of dough are obtained in each cycle instead of only one.

The capacity of production is multiplied by four, reaching the amount of 9600 pieces/hour.

In this model the maximum diameter of the piston is 80mm, therefore the maximum weight that can be obtained is 300g.